Home » Applications » Molds & Dies » Plastic Injection Molds

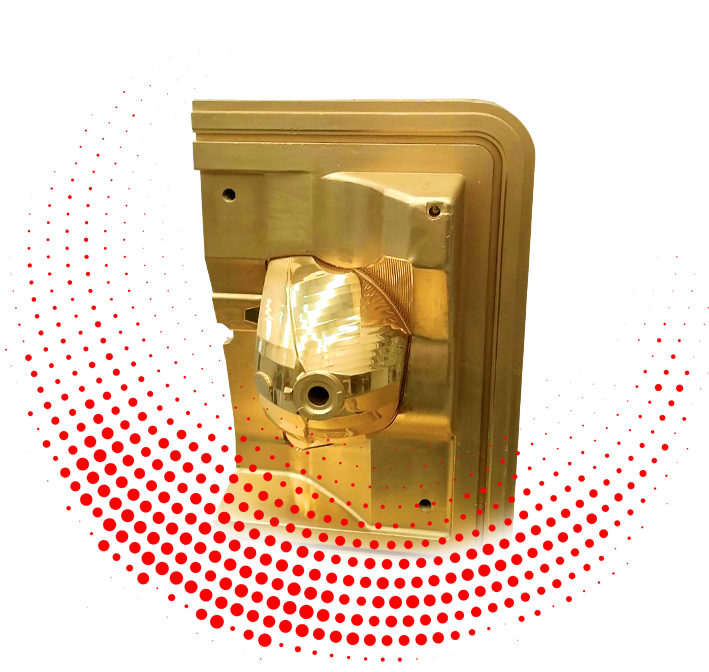

Our PVD coatings are specially developed to protect plastic injection molds from abrasive wear, improve de-molding characteristics, give scratch protection on the mirror-polished surfaces, enhance corrosion resistance and increase the efficiency and reliability of the tools.

With over 30 years of experience in coating molds and dies, our R&D center is constantly developing high performance coatings dedicated to Plastic Injection.

Say goodbye to frequent replacements. Our advanced coatings result in increased tool life, providing durability that stands the test of time. This translates to cost savings and efficiency in your Plastic Injection process.

Our coatings go beyond the surface, optimizing maintenance cycles for plastic injection tools. Experience longer intervals between maintenance requirements, reducing downtime and enhancing overall operational efficiency. Ensuring your Plastic Injection processes remain agile and responsive to evolving production demands.

Primus Coating is your partner in advancing Plastic Injection capabilities. Elevate precision, extend tool life, and embrace operational efficiency with our cutting-edge PVD coating solutions.

Our team is ready to provide personalized solutions tailored to your needs.

Whether you have questions, need guidance, or want to explore our offerings,

our experts are here to assist you.

© Copyright PrimusCoating 2025. All Right Reserved.

Developer by Yooper Digital Marketing