Home » Applications » Molds & Dies » Stamping and Forming

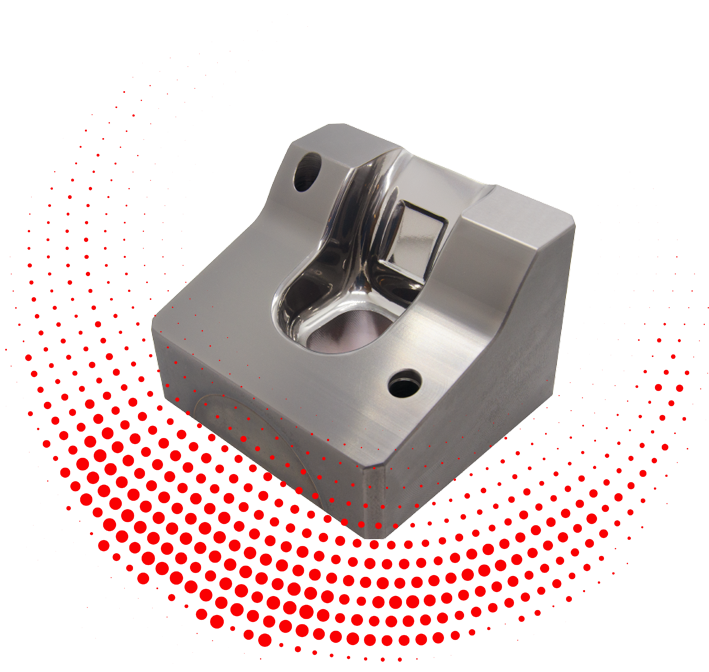

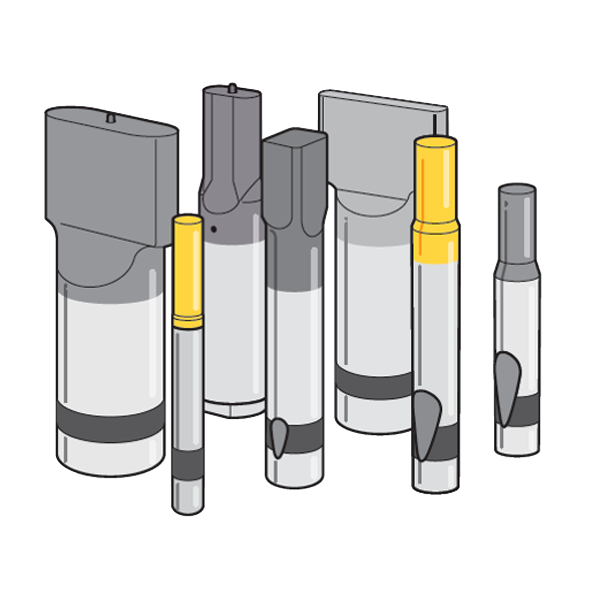

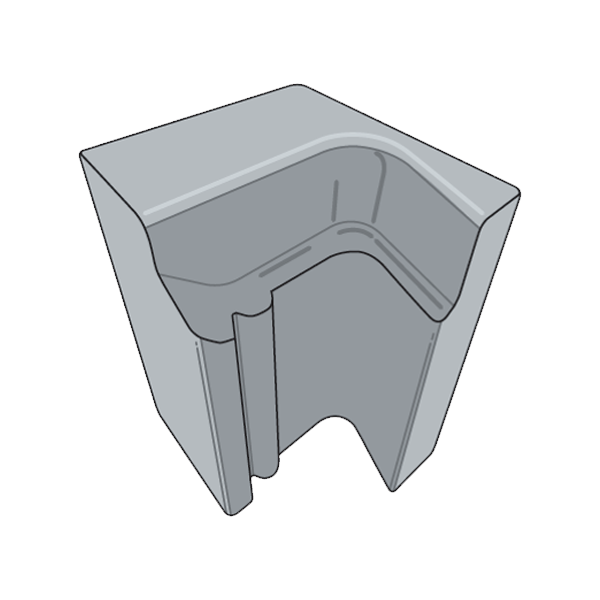

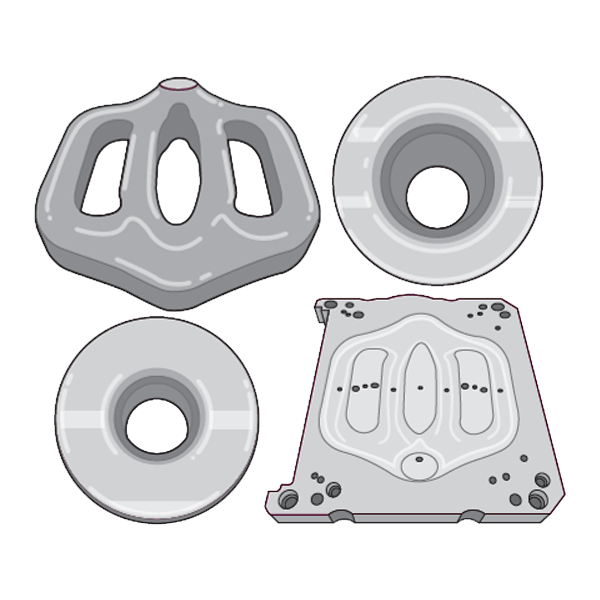

Our PVD coatings are specifically designed to reduce friction, reduce galling, scoring and material adhesion. Especially in medium to high strength material forming applications.

With over 30 years of experience in the segment, our R&D center is continuously developing and improving high-performance coatings dedicated to molds and dies.

Redefine surface hardness with Primus Coating's advanced recipes. Our coatings provide a robust shield, enhancing the durability of molds and dies in various stamping and forming applications.

Combat corrosion challenges effectively. Primus Coating's PVD coatings offer superior corrosion resistance, ensuring the longevity and reliability of molds and dies in diverse working conditions.

The high hardness of the coating is up to 3 times higher than the hardness of tempered steel.

Less rejected or reworked panels due to stable panel quality.

Due to the low coefficient of friction of the coating, additonal lubrication can be reduced and in some cases elimated from the process.

The coating process eliminates material adhesion and scoring reducing press down-time for cleaning.

The PVD coating protects the geometry of the tool ensuring high quality stamped parts.

In cases where DUPLEX processes are used.

Environmentally friendly process. No use of harmful chemicals as is the case with hard chromium and nickel plating.

Our team is ready to provide personalized solutions tailored to your needs.

Whether you have questions, need guidance, or want to explore our offerings,

our experts are here to assist you.

© Copyright PrimusCoating 2025. All Right Reserved.

Developer by Yooper Digital Marketing