PrimusCoating

Technology

Home » Technology

Global Expertise,

Local Solutions

With R&D centers in Japan and Switzerland, our team leverages vast expertise and experience to provide the most innovative, proven, and application-specific solutions. PrimusCoating offers not only high performance coatings but also specialized services, including cleaning, de-coating, and pre/post-coating solutions.

Our commitment to R&D is deeply ingrained in our collaboration between Japan and Switzerland, where pioneering minds work tirelessly to push the boundaries of coating technology.

Experience the power of global collaboration with PrimusCoating. Choose a partner that seamlessly integrates R&D excellence and a unified approach to technology, ensuring unmatched solutions for your coating requirements worldwide.

PrimusCoating

Technology

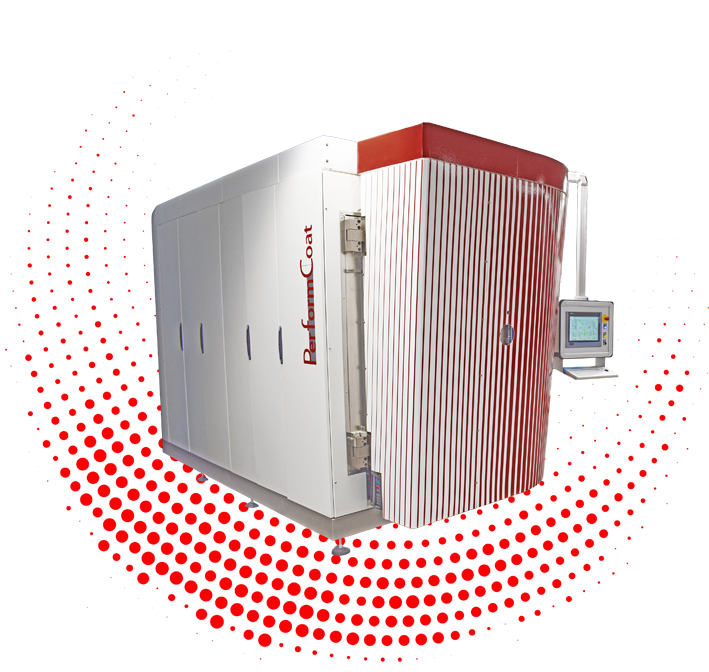

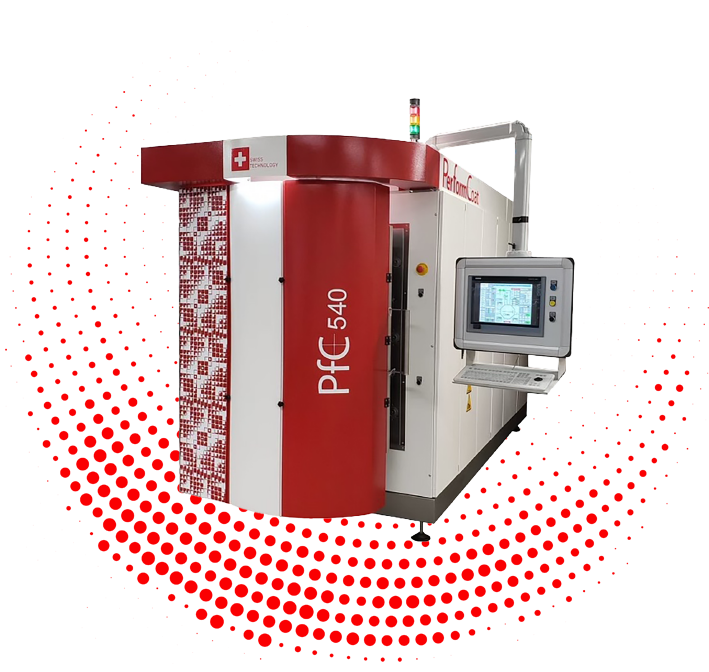

Every PrimusCoating facility operates on the same cutting-edge technology platform, PerformCoat, and adheres to standardized operating procedures. This unwavering commitment ensures a uniform level of quality and service, delivering excellence across all our locations.

Our comprehensive range of thin film technologies spans PVD by Cathodic Arc and Sputtering to PeCVD by DC and RF, as well as combined treatments. We go beyond conventional offerings with innovative solutions for Plasma Nitriding, providing a diverse toolkit for your coating needs.

PVD Coating Technology

PVD / PeCVD Machines

PerformPVD Equipment for Hard Coating

- Easy to operate

- Precise, fast

- Efficient

- Affordable

- Low running cost

- Locally supported

PVD Cathodic Arc Evaporation

- Planar, round, filtered Arc cathodes

- Coatings with up to five different target materials

- Coating layers with adjustable properties for toughness, hot hardness, wear resistance, oxidation resistance, and color

- Mono, multi, nano, and gradient coating structure

- Tightest coating thickness distribution in the industry

- Flexible combination of plasma as well as metal ion etching

- Equipment customizable to required application, throughput and flexibility

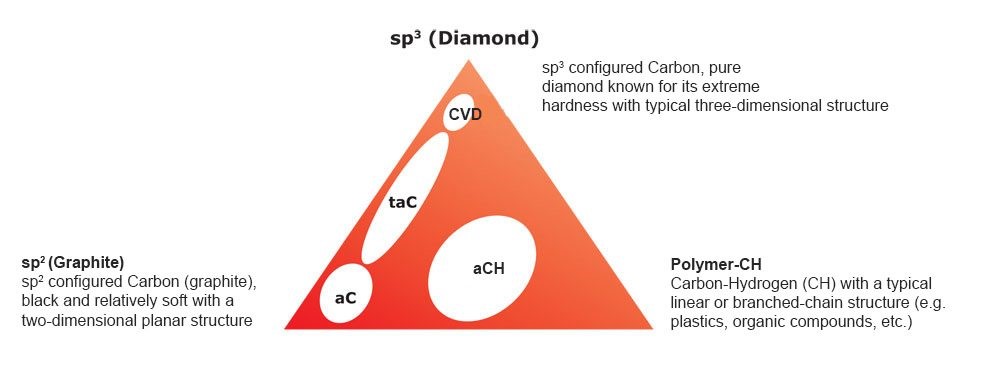

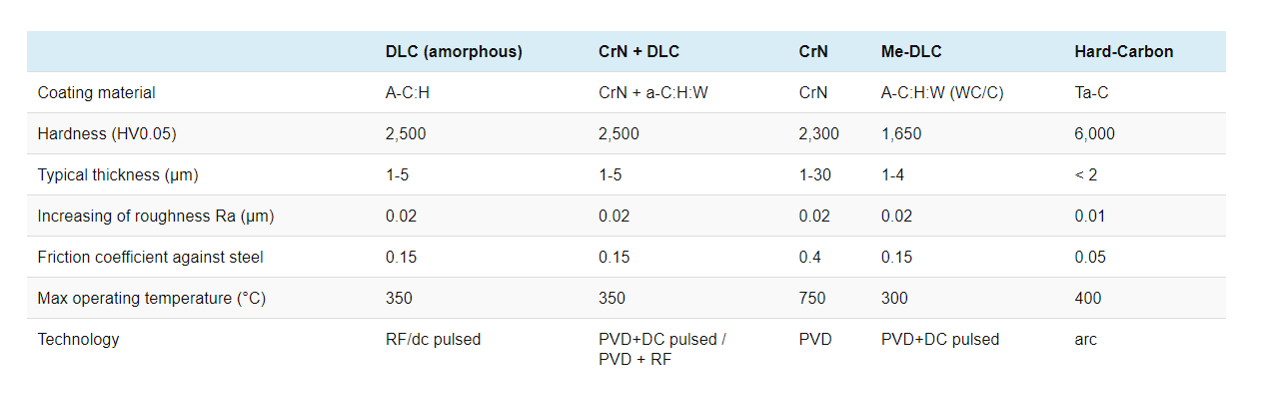

PeCVD/DLC Technologies

RF DLC

- Applications (for small and medium volume parts): racing, medical, high quality plastic molds, and watch industry for decorative purposes

- High-density layer, high-compressive stress, very low friction coefficient

- Limited loading capacity and flexibility

- Very short cycle time

Pulsed DC

- Most suitable for high volume applications: large equipment available with little limitations to batch loading

- Coatings not as dense and hard as DLC by RF

- Typical applications: parts for textiles machinery, general machine parts, automotive engine components, and large/long parts

Hybrid/Multilayer

- Applications: large volume in automotive and aerospace industry

- Combination of PVD sputtering or arc coating and PeCVD in the same batch

- Sputter/arc interlayers designed to make best transition between substrate material and DLC layer leading to improved adhsesion and a wider range for substrate materials

- Duplex treatments, combined Plasma Nitride in just one process

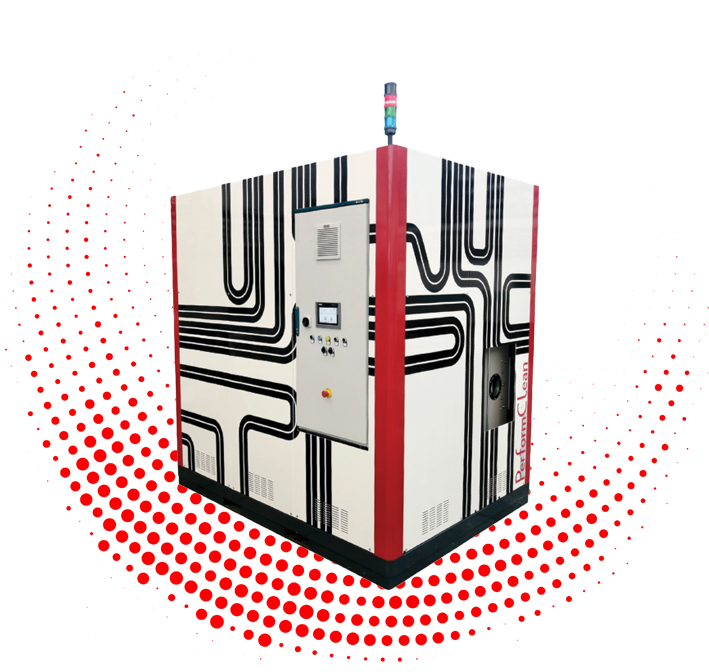

Cleaning Technology

Cleaning Machines

PerformClean machines are closed-circuit, single-chamber vacuum-cleaning and vacuum-drying-cleaning machines which work with modified alcohols and solvents.

- Pre-cleaning by spray-washing

- Full immersion in cold and hot solvent combined with ultrasonics

- Rinsing

- Final cleaning by solvent vapor

- Vacuum drying to achieve spotless condition

- The running costs are exceptionally low

Edge Preparation and Polishing Technology

Drag Finish Machines

Takes control of your cutting edges with our PerformDrag

- Create a well-defined hone

- Strengthen the cutting edge

- Avoid microchipping due to grinding

- Prepare edge for high performance coating

- Deburr HSS tools

Brush Machines

Our PerformBrush is a new generation of CNC brushing equipment

- Improve the surface roughness by removing coating droplets

- Polish carbide tools prior to finish grinding

- Avoid build-up edge for machining of soft materials

- Achieve improved chip formation and chip flow

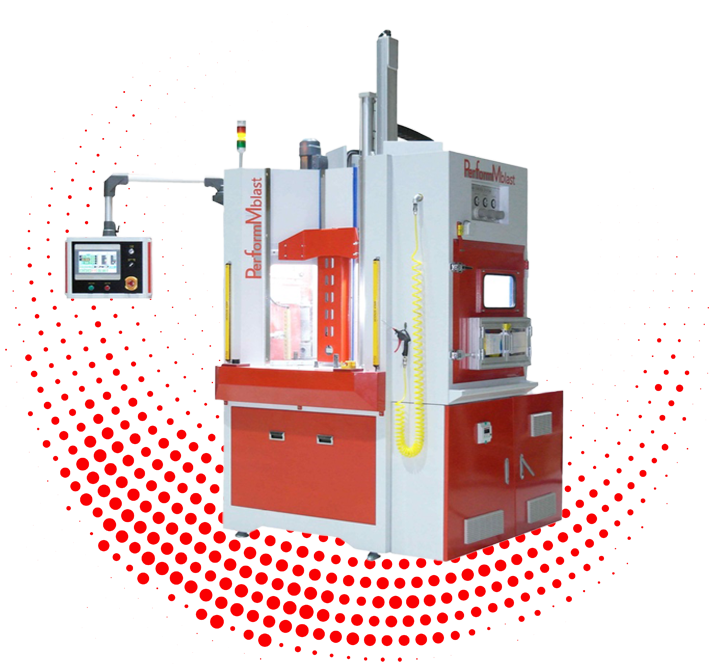

Micro Blasting Machines

PerformMBlast for automatic edge preparation of gear cutting and indexable tooling

- For media with a mesh size up to 500

- Creates a well defined hone on hobs and shaper cutters

- Stabilizes the cutting edge to increase the number of regrinds

- Prepare edge for high performance dry hobbing

Technology Development Partner

- OSG Corporation

- 3-22 Honnogahara

- Aichi 442-8543, Japan

- Phone: +81 70-3193-5061

- www.osg.co.jp

Interested in equipment?

Discover high-performance PVD and PeCVD coating solutions tailored to your needs. From entry-level setups to large-scale manufacturing, PerformCoat offers comprehensive support, from installation to training. Contact us today to learn more.

Interested in equipment?

Discover high-performance PVD and PeCVD coating solutions tailored to your needs. Contact us today to learn more.