HP Aero

High Performance Coatings

for Cutting Tools

Explore our coatings:

High Performance Coatings For Cutting Tools

Home » Coatings » High Performance Coatings for Cutting Tools » HP Aero

HP Aero

HP Aero – High Toughness and Low Friction

HP Aero coating is a game-changer in aerospace parts machining. Boasting high toughness and low friction, HP Aero is meticulously crafted to excel in the machining of high tensile strength materials. The primary materials used in the aerospace industry are titanium (Ti) and nickel (Ni) based alloys as well as stainless steel.

Key Features

Applications

Choose HP Aero from Primus Coating for precision, toughness, and reduced friction in aerospace machining. Experience the cutting-edge technology that propels your aerospace components to new heights of excellence.

HP Aero coating is a game-changer in aerospace parts machining. Boasting high toughness and low friction, HP Aero is meticulously crafted to excel in the machining of high tensile strength materials. The primary materials used in the aerospace industry are titanium (Ti) and nickel (Ni) based alloys as well as stainless steel.

Key Features

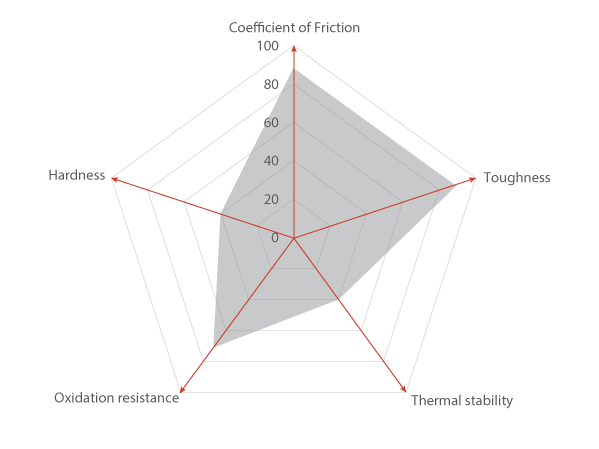

- High toughness: HP Aero is engineered with high toughness, ensuring the resilience and longevity needed for demanding aerospace applications

- Low coefficient of friction: Experience reduced friction by enhancing the efficiency and precision of your machining processes with HP Aero

Applications

- High tensile strength materials: Achieve precision in machining materials with high tensile strength, ensuring reliability in aerospace applications

- Ti and Ni based alloys: HP Aero excels in machining titanium (Ti) and nickel (Ni) based alloys, delivering consistent performance in aerospace components

- Stainless steel: Navigate the challenges of machining stainless steel with the prowess of HP Aero, ensuring precision and efficiency in aerospace manufacturing

Choose HP Aero from Primus Coating for precision, toughness, and reduced friction in aerospace machining. Experience the cutting-edge technology that propels your aerospace components to new heights of excellence.

Series

High Performance

Composition

AlTiCr Based

Hardness

30 GPa

Thickness

2 ~ 3 µm

Color

Silver

Materials

- Stainless Steel

- Super Alloys

Applications

-

Milling

Drilling

Threading

Structure

Multilayer

Oxidation Temperature

700ºC

Surface Roughness (Ra)

0.10 ~0.20 Ra

Coefficient of Friction

0.1

Coating Deposition Temperature

450ºC

Talk with an expert!

Our team is ready to provide personalized solutions tailored to your needs.

Whether you have questions, need guidance, or want to explore our offerings,

our experts are here to assist you.