Technology

PerformCoat offers a wide range of thin film technologies from PVD by Cathodic Arc and Sputtering to PeCVD by DC and RF as well as combined treatments and innovative solutions for Plasma Nitriding. Thanks to their vast expertise and experience, the group can offer the most innovative, proven, and application-specific solutions for coatings as well as for cleaning, de-coating, and pre/post coating treatments.

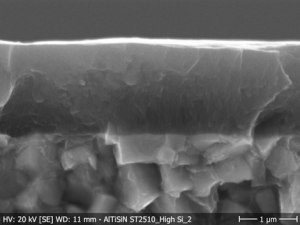

PVD Cathodic Arc Evaporation

- Planar, round, filter

- Coatings with up to four different target materials

- Coating layers with adjustable properties for toughness, hot hardness, wear resistance, oxidation resistance, and color

- Mono, multi, nano, and gradient coating structure

- Tightest coating thickness distribution in the industry

- Flexible combination of plasma as well as metal ion etching technologies

- Equipment customizable to required throughput and flexibility

PeCVD/DLC Technologies

RF Technology:

- Applications (for small and medium volume parts): racing, medical, high quality plastics molds, and watch industry for decorative purposes

- High-density layer, high-compressive stress, very low friction coefficient

- Limited loading capacity and flexibility

- Very short cycle time

Pulsed DC

- Most suitable for high volume applications: large equipment available with little limitations to batch loading

- Coatings not as dense and hard as DLC by RF

- Typical applications: parts for textile machinery, general machine parts, automotive engine components, and large/long parts

Hybrid / Multilayer

- Applications: large volume in automotive and aerospace industry

- Combination of PVD sputtering or arc coating and PeCVD in the same batch

- Sputter/arc interlayers designed to make best transition between substrate material and the DLC layer leading to improved adhesion and a wider range for substrate materials

Turkey

Turkey