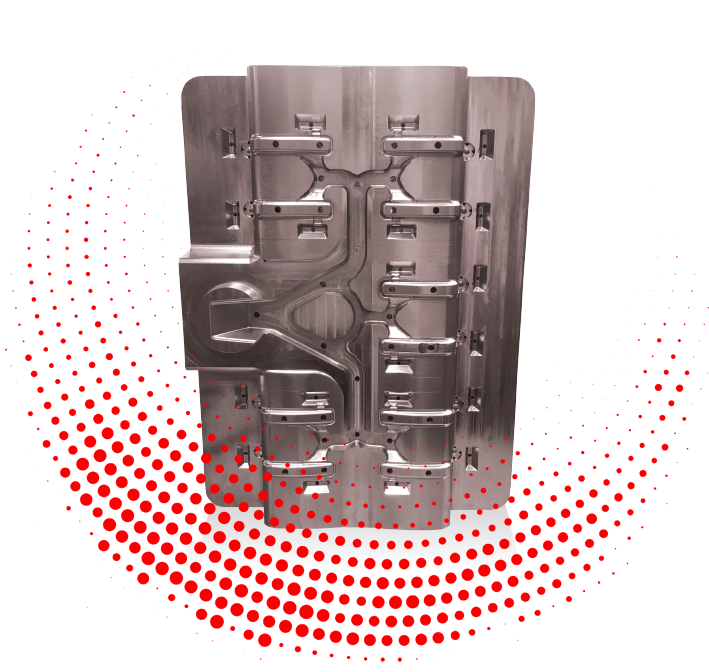

Home » Applications » Molds & Dies » Aluminum Die Casting Molds

Our PVD coatings are specially developed to reduce thermal fatigue, reduce erosion and prevent material adhesion in aluminum die casting molds.

Besides increased tool life, the coatings reduces maintenance of the tools, reduces scrap and re-work ensuring high quality parts are produced every time.

With over 30 years of experience in coating core pins as well as cavities, our R&D center has been developing high performance coatings dedicated to aluminum and magnesium die casting applications.

Immerse your Aluminum Die Casting processes in a new era of excellence with Primus Coating’s specially crafted PVD coatings. Engineered to perfection, our coatings are tailored to meet the unique demands of the Aluminum Die Casting industry, delivering a range of advantages.

Our coatings redefine surface hardness, providing a robust shield to aluminum die casting molds. Say goodbye to wear and tear. And welcome extended tool life that withstands the rigors of high-pressure casting.

Combat heat cracks effectively with our specialized PVD coatings. Primus Coating’s technology addresses the thermal challenges in aluminum die casting, ensuring molds remain crack-free and deliver consistent results.

Our team is ready to provide personalized solutions tailored to your needs.

Whether you have questions, need guidance, or want to explore our offerings,

our experts are here to assist you.

© Copyright PrimusCoating 2025. All Right Reserved.

Developer by Yooper Digital Marketing